Sony has announced the creation of a new LCD technology called Hybrid FPA (field-induced photo-reactive alignment). This new Hybrid FPA is designed to improve LCD response time, contrast ration, panel stability, and production speed, bringing the LCD one step closer to the plasma, a type of TV Sony used to make itself. As the guys over at Engadget put it, “this boils down to Sony finding a better way to wrangle unruly liquid crystal molecules (LCMs) into more optimal alignments — which is important since this affects how light passes and therefore how images are resolved.” Previously, LCD makers have fought off ghosting and improved response time by raising the hertz on their television from the traditional 60hz to 120hz and to the now standard 240hz for 3D TVs. With this new Hybrd FPA LCD technology, Sony is going to attempt to further reduce the response time on their sets, thus eliminating the need for raising the Hz count in the near future. 3D TV fans will benefit from this as well. While many complain that 3D can look dark, this new technology will boost future televisions’ ability for a higher contrast ratio and offer a brighter picture. It’s unclear when Sony is looking to commercialize this technology, though we hope for sooner rather than later.

As always, hit the jump for the official press release.

[Via Sony]

Sony develops “Hybrid FPA”, a novel liquid crystal alignment technique that achieves faster response time for liquid crystal displays

Sony Corporation (hereafter ‘Sony’) has developed “Hybrid FPA (field-induced photo-reactive alignment)”, a new liquid crystal alignment technique which enables a significantly faster response time for liquid crystal displays. Fast responses of less than 3ms have been achieved in test cells through this technology. Aside from contributing to ‘picture quality enhancement in 3D and high frame rate video’, this technology will improve ‘product stability’ during the display panel manufacturing process as well as after long-term use. Additionally, this technology will achieve production efficiencies by reducing the manufacturing process and time.

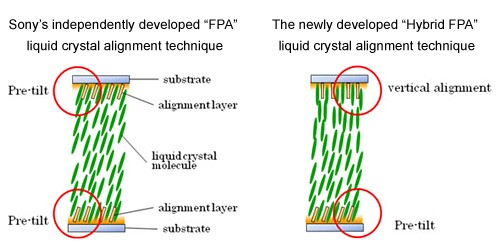

Sony previously developed the “FPA *1” high-speed liquid crystal response alignment technique based on vertical alignment (VA) liquid crystal modes. One method for improving liquid crystal response time is to generate pre-tilt of the liquid crystal molecules. “FPA” technique uses the alignment layer developed by Sony and maintains pre-tilt of liquid crystal molecules by irradiating UV while applying voltage in manufacturing process. This facilitates the stable and even alignment of the liquid crystal molecules *2, thus achieving improvements in both liquid crystal response time and the contrast ratio. In addition, this has made it possible to eradicate the Mura (uniformity problem) in the display as well as to eliminate the ‘sticking image’ that can occur after long-term use.

The new “Hybrid FPA” technology is the result of further development of the aforementioned “FPA” technology with its superior features. “Hybrid FPA” technology has achieved an even faster liquid crystal response time by maintained the pre-tilt on just one side of the substrate alignment layer (see illustration). Furthermore, this new technology has succeeded in facilitating drastic improvements in liquid crystal response time, especially faster movement of liquid crystal molecule when decreasing the voltage which was previously difficult to achieve, as well as higher contrast.

This technology will be presented on December 2 at IDW ’10 (International Display Workshops), a display technology conference to be held in Fukuoka City, Japan from December 1 to 3. (http://www.idw.ne.jp/home.html)

Sony is jointly developing alignment layer materials with JSR Corporation (hereafter, ‘JSR’), a leading company in electronic materials and display materials, for early commercialization of this technology. Hereafter, Sony plans to further accelerate its development of the technology with JSR’s highly functional alignment layer materials and stable material quality.

You must be logged in to post a comment.